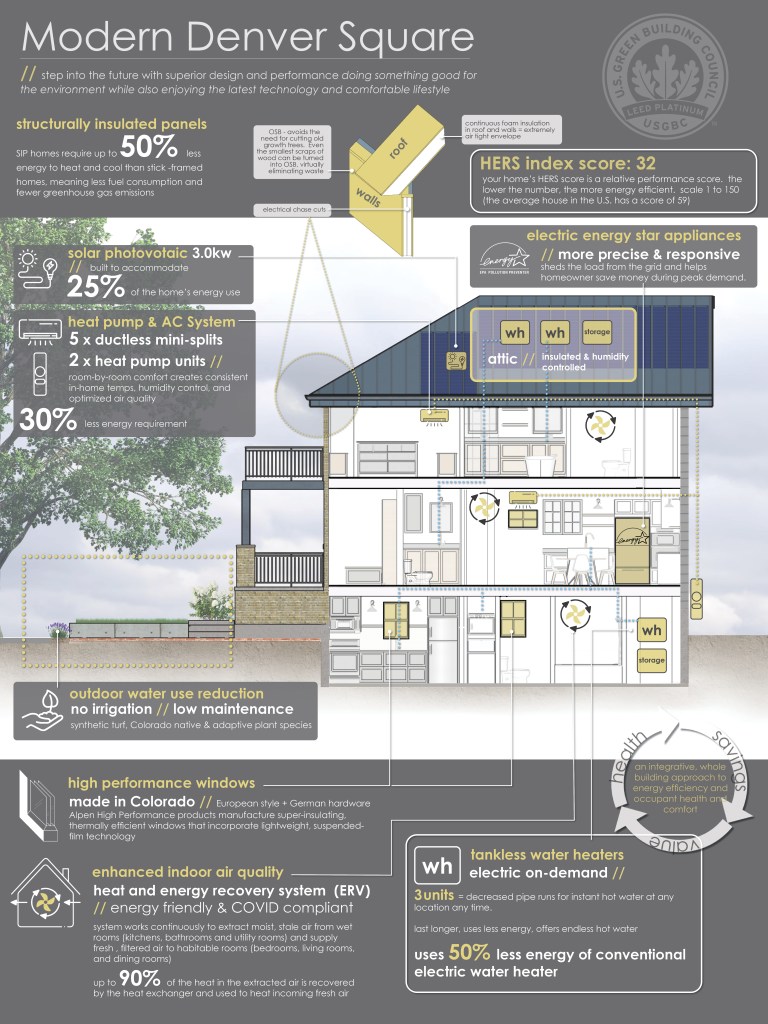

At times it is difficult to quantify in the simplest terms the value in our building process and the materials that make a high performing energy efficient home. One of the reasons why the value is hard to communicate is because we are building by way of the future. Municipal building codes are moving towards higher efficiency standards but we are still leaps and bounds ahead of what is required so it falls on our shoulders to not only educate the potential homeowner but the real estate agent. For it would be a shame if someone bought this house and didn’t understand how all the systems come together to achieve energy efficiency and the highest level of occupant health and comfort. The ideal homeowner will take pride in living in a LEED Platinum Certified home that not only is good for the environment while enjoying the latest technology and a healthy/comfortable lifestyle.

It is our hope that the below infographic helps the common person to understand and value an all electric energy efficient home. We’ve also included Green Energy Details below with links to the actual product websites.

GREEN ENERGY DETAILS:

Thermal Comfort / High Performance – Targeting HERS score of below 35.

Structurally Insulated Panels. The home is built with pre-fabricated wall panels that consist of an insulated foam core sandwiched between OSB. The thermal envelope of the walls and roof are continuous insulation and allow for an extremely airtight building envelope.

All Electric Home. All electric appliances, water heaters and HVAC system. The use of clean energy eliminates to the risk of air pollution from gas appliances and dependency on fossil fuels and lower utility bills offset by the building integrated roof top solar panels.

Renewable Energy

Solar Panels. Mia Sole architectural, high efficiency building integrated 3.0KW array.

High Performance Windows. Alpen High Performance Products manufactures super-insulating, thermally efficient residential windows utilizing three decades of experience incorporating lightweight, suspended-film technology. Tilt-Turn windows with German hardware and single hung windows are utilized in the house. Made in Colorado with local support and services.

Enhanced Indoor Air Quality

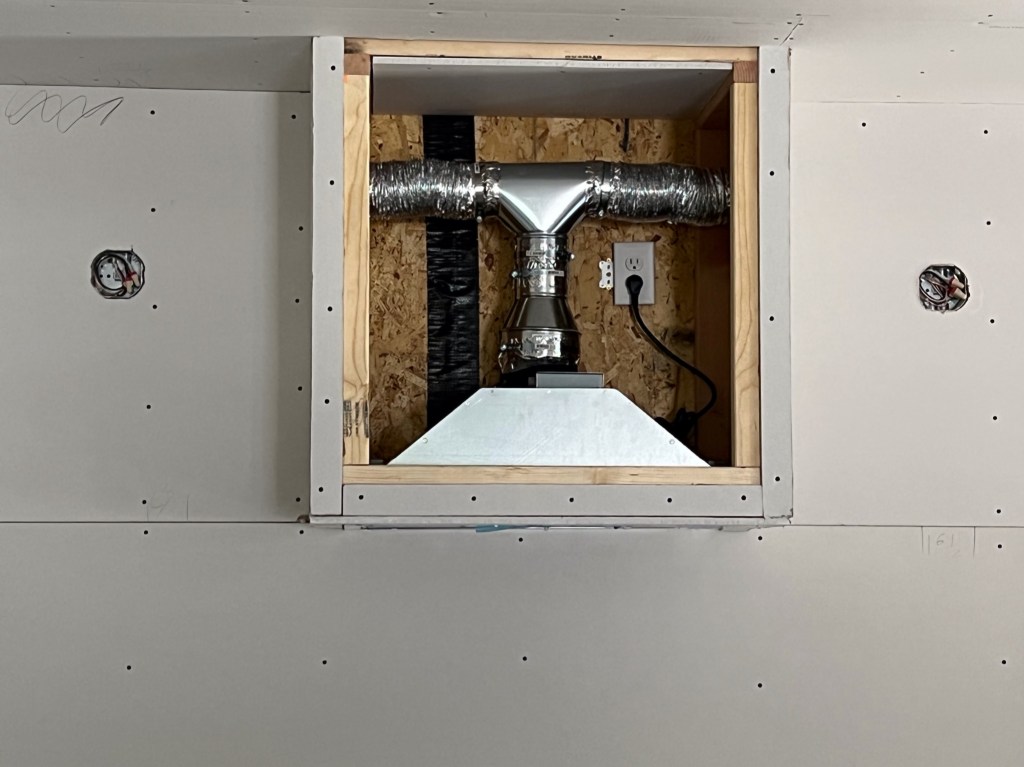

Heat and Energy Recovery System (ERV). by Zehnder for high-performance buildings. Provides the home with a comfortable, healthy and energy efficient indoor climate. The whole house heat recovery ventilation system works continuously to extract moist, stale air from wet rooms (kitchens, bathrooms and utility rooms) and supply fresh, filtered air to habitable rooms (bedrooms, living rooms, and dining rooms). Up to 90% of the heat in the extract air is recovered by the heat exchanger in the unit and used to heat the incoming fresh air. Allergy friendly, COVID compliant.

Optimized Energy Performance

All Electric Daikin Heat Pump & A/C System. An HVAC zoning solution for room-by-room comfort. The home is equipped with two Daikin Heat Pump outdoor units paired with five interior heads for a customizable zoned-system creating more consistent in-home temperature, humidity control and optimized air quality control.

Tankless Electric On-demand Water Heaters. These units last longer, use less energy, offer endless hot water. Three units are provided ensuring decreased pipe runs for instant hot-water at any location at any time.

Energy Star Appliances. Electric appliances tend to be more precise than gas ones. For example, having more control over your range or even the temperature of the water in your washing machine.

Low Emitting Materials

Natural Solid Wood Floors

NuCore Rigid Luxury Vinyl Plank Floors

Green Guard Rated Carpet

Low VOC Emitting Paint

Long Lasting and Durable Materials

Standing Seam Metal Roof

Brick Masonry Facade

Cementitious Siding

Outdoor Water Use Reduction

Professionally designed landscape. Plant selection includes Colorado native and adaptive species that requires no irrigation and includes artificial turf lawn and permeable paving.

Unique home features

Re-used existing concrete foundation and walls of the 1941 bungalow.

Re-used original brick from the demolition of the garage and house.