We are chipping away at the not so glamorous but necessary tasks of interior framing and weatherproofing so that plumbing, electrical and HVAC systems can be installed. Scott spent the end of February and early March framing all the bedrooms, bathrooms and closets and we selected our kitchen and bathroom fixtures so that the plumber had everything he needed. The plumber was in and out within the past two weeks and our next step is to prepare for HVAC and then electrical. We have been refining the electrical plans and selecting fixtures for this next phase. But before electrical can begin, the house has to be dried in.

In parallel to plumbing and electrical prep Scott has been weatherproofing the house which is a 5 step process:

The Roof: We rolled out the Siga Majcoat breathable membrane that is taped at the seams with Siga Wigluv construction tape. The products create a wind tight and rain-proof roof.

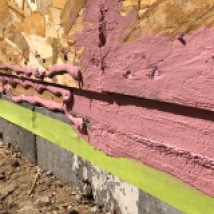

Filling Facade Joints and Seams: All the transitions between the SIPs are filled with a pink R-guard adhesive.

Liquid Flashing: At every window and door rough opening a red ‘fast flash’ R-guard liquid is applied.

Liquid Weatherproof Membrane: A black liquid weatherproof membrane is roller applied to the entire exterior facade.

Windows and Doors: We have begun to install windows and doors on the first floor where the liquid applied weatherproofing is finished.

In the next week we should be ready to install the rest of the windows. Then we can set the electrical contractor loose. We are also lining up contractors to get underground utilities installed.